Medical devices rely on advancements in extrusion technology

A number of factors are driving the need for advancements in composite shaft constructions, such as:

- Demand for smaller shaft diameters

- Reduced wall thicknesses

- Improved functionality

- Variable properties along the length

- Variable properties throughout the cross section

At the same time, demand for improved manufacturing economies and process validations are shifting the focus from manual assembly to continuous manufacturing technologies.

Putnam Plastics continues to lead in high-tech medical tubing technologies

Putnam Plastics leverages a wide range of material expertise, in-house tool making and tube processing technologies to offer the latest in continuously manufactured composite shafts. These include integration of novel materials such as polyimide, PEEK or fluoropolymers for liners, variable wire reinforcements along the shaft length, and variable durometer outer layers along the length of the shaft.

Putnam creates solutions—even if it means developing new technologies

For example, a customer was concerned that a dilator could loosen from its sheath during the procedure, yet still wanted a soft durometer on the distal end.

As a result, Putnam introduced it’s patented TIE™ tubing technology. This technology produces a soft distal tip that does not cause damage during the procedure—while removing the physician’s apprehension of the tube dropping out because of a stiffer proximal end.

State-of-the-art technologies offered at Putnam

We continually develop ways to streamline the manufacturing process. Our proprietary technologies include

- Tri-TIE™ a continuous extrusion technology with variable durometer in the catheter shaft

- Taper-TIE™ a continuous extrusion with variable durometers and dimensions along the tubing

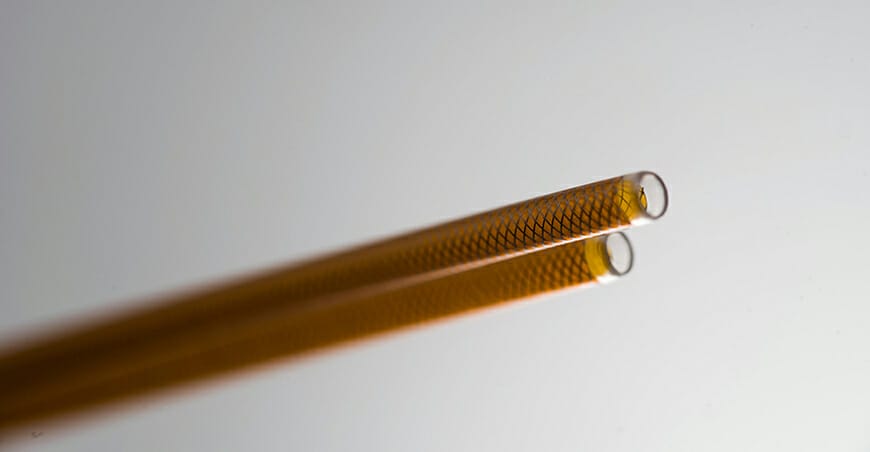

- Braided TIE™ for multi-durometer braided catheter shafts

- Super-TRI™ a tri-layer tubing that reduces elongation, while boosting both tensile and burst strength

We also offer advanced technology to strengthen the shafts used in minimally invasive devices for cardiovascular, neurovascular and endovascular specialties

- Variable Braid & Coil is for tubing that changes its pic or pitch over the catheter shaft length

- Polyimide Shaft Liners provide an very thin-walled tube with superb high tensile strength

- Coil & Braid Reinforced Multi-lumen Tubing has an encapsulated braid or tubing in the walls to improve burst, torque, crush, kink and radial strength

- Proximally Reinforced Shafts

Other improved technologies such as:

- Marker Bands that are tungsten-filled thermoplastics which form a molecular bond with the catheter, so it won’t slip off

- Dilators and Sheath Extrusions improve upon more traditional methods, to give you the most advanced medical device manufacturing options

Why choose Putnam Plastics high-tech extrusion technologies?

- We thrive on developing high-end products—ones other manufacturers find too challenging

- Our turnkey solutions, engineering expertise, and ability to provide very complex medical components that our competitors cannot, translates into top-notch medical device assembly for you

- With end-to-end device assembly, we can limit costs through new technologies. We research and develop tubing advancements to transform labor-intensive methods into streamlined processes

For over 38 years, our global partners have been consulting with us for creative solutions to their tubing challenges. How can we put our expertise to work for you?