Putnam Plastics has over 40 years experience as a high-tech extrusion technology leader

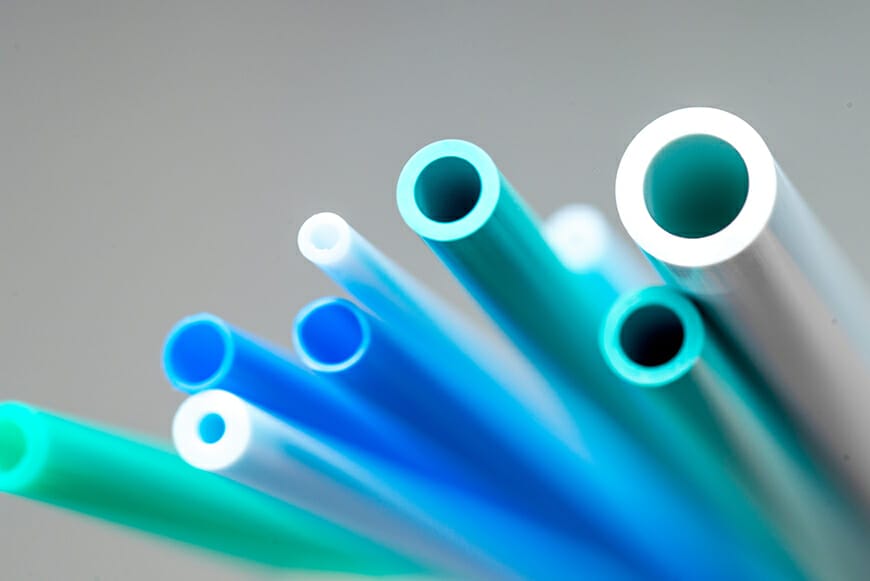

Putnam Plastics Corporation has been a technology leader in the field of medical catheter extrusions for nearly four decades. Putnam offers the widest range of extrusion technologies for medical devices in the industry. Medical device companies from around the world continue to rely on Putnam Plastics for one-stop-shopping of medical catheter extrusions technologies and minimally invasive tubing.

Putnam provides you with numerous medical plastic extrusion options

We specialize in continuous manufacturing technologies that minimize manual operations to produce complex composite catheter designs.

From more simple single lumen tubes and double-D tubing to complex multi-lumen tubes, we’ve produced nearly every configuration imaginable.

Our coextrusion and tri-layer extrusion technologies offer you a wide range of functionality, features and material options. Both our intermittent extrusions and tapered tubing offer increased variability along the shaft length.

Braiding, coiling and linear wire reinforced extrusions provide additional structural support to medical shafts.

Our medical monofilament extrusions are ideal for minimally invasive applications that need non-metallic properties, while Putnam’s wire coating extrusion allows for continuous plastic sleeving for an extensive spectrum of performance applications.

Putnam’s facility offers a wide range of extruding capabilities

At our medical extrusion facility, we have over 30 extruders in a range of sizes up to 2 inches, (50.8 mm), 3D modeling and finite element analysis tool design, CNC and EDM tool manufacturing. We have the ability to produce a wide range of catheter tubing sizes.

Our dedicated clean manufacturing space within our 37,000 square foot (3431.4 square meters) facility allows our experienced staff to develop extrusions for challenging medical catheters and minimally invasive applications, scale processes and transition to manufacturing.

You get optimum quality assurance with our advanced medical manufacturing facility

Our state-of-the-art medical manufacturing facility is ISO 13485:2016 certified, reaffirming our goal of maintaining a quality system of the highest possible standard.

Fully equipped laboratory for incoming raw materials and on-line statistical process control as well as a vast array of contact and non-contact inspection technologies ensure that every product requirement is met.

Why partner with Putnam Plastics for your medical plastic extrusions?

Our end-to-end device assembly allows us to pass on reduced costs to you through new technologies.

We research and develop tubing advancements to replace labor-intensive products with more agile processes, but still have the space to implement full reflow and hand lay-up capabilities as needed.

For decades, we’ve provided our global clientele innovative solutions to their most complex tubing issues. Find out how our engineering expertise can benefit you by talking with one of our knowledgeable representatives today.