DAYVILLE, CT, USA – (December 7, 2011) – Putnam Plastics Corporation, a PolyMedex Discovery Group company and leader in advanced extrusions for minimally invasive medical devices, has eliminated the traditional hand lay-up manufacturing process of medical guide catheter shafts with their new Tri-Tie™ extrusion technology.

Putnam’s continuous technology builds the three-layer composite shafts without manual assembly and staff, resulting in improved product reliability and lower cost.

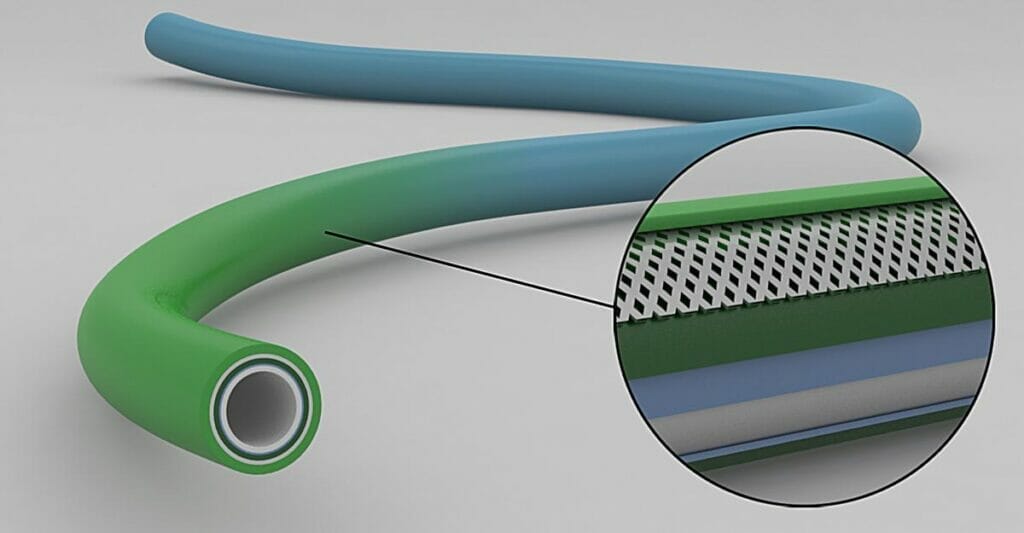

Guide catheters are commonly used to access endovascular sites and deliver balloons, stents, guide wires, contrast media and other devices. These catheters are costly and challenging to manufacture due to complex shaft requirements, which include a lubricious inner layer, a braided stainless steel middle layer, and a variable durometer outer layer. Product performance can vary due to poor bonding between the layers and at the union of the outer layer segments, where hinge points occur.

Putnam Plastics’ Tri-Tie extrusion technology eliminates traditional manual assembly of multiple components with proprietary, continuous processing that creates a three-layer composite shaft with maximum adhesion between the layers for improved performance. It also provides a more gradual transition of the varying durometer outer layer without bonding or hinge points.

“Tri-Tie guide catheter shaft manufacturing rethinks the conventional approach to achieve a more integrated and reliable component,” said Ray Rilling, Director of R&D at Putnam. “While the technologies and materials used for this process have a proven track record in vascular catheter applications, the combination of these technologies in a single component is a hallmark of Putnam’s innovative manufacturing approach.”